When customizing a backpack, the choice of material is often the key factor that determines the final product’s performance, appearance, and lifespan, and among all options, nylon and polyester stand out as the two most widely used synthetic fabrics in the global backpack manufacturing industry. We’ve witnessed countless clients struggle with the same question: “Should I choose nylon or polyester?”

Whether you’re looking to customize a durable work bag for your team or design a lightweight, colorful backpack for your brand, this article will serve as your essential guide to choosing between nylon and polyester, because when it comes to custom backpacks, the right material is what truly brings your vision to life.

Nylon vs Polyester: Origins and Production

To choose the best material for your custom backpack, understanding the origins and production of nylon and polyester helps reveal why they perform differently.

These two synthetic fibers, though both derived from petroleum, were developed for distinct purposes and crafted through unique processes, shaping their inherent strengths in backpack applications.

A Brief History: From Lab to Market

Nylon: The “Tough” Material Born for War

Nylon was first created in 1935 by Wallace Carothers at DuPont (USA) as a silk alternative. By 1939, it debuted at the World’s Fair and gained fame for its use in WWII military gear (parachutes, tents, ropes)—where extreme durability was critical.

After the war, it entered civilian life (e.g., stockings, bags) and became a go-to for outdoor and high-performance backpacks due to its legendary toughness.

Polyester: The “Practical” Fiber for Everyday Use

Polyester’s story began in 1941 when British scientists invented polyethylene terephthalate (PET, polyester’s base).

By the 1950s, DuPont commercialized it as “Dacron,” and it quickly dominated affordable clothing (shirts, suits) and home textiles thanks to its low cost and wrinkle resistance. Later, its lightweight, sun-resistant traits made it popular for everyday bags and school backpacks.

How They’re Made: Key Production Differences

Though both start from petroleum byproducts, their manufacturing processes create distinct fiber structures:

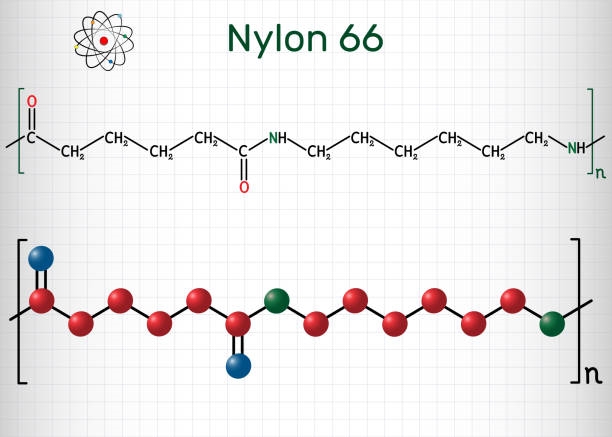

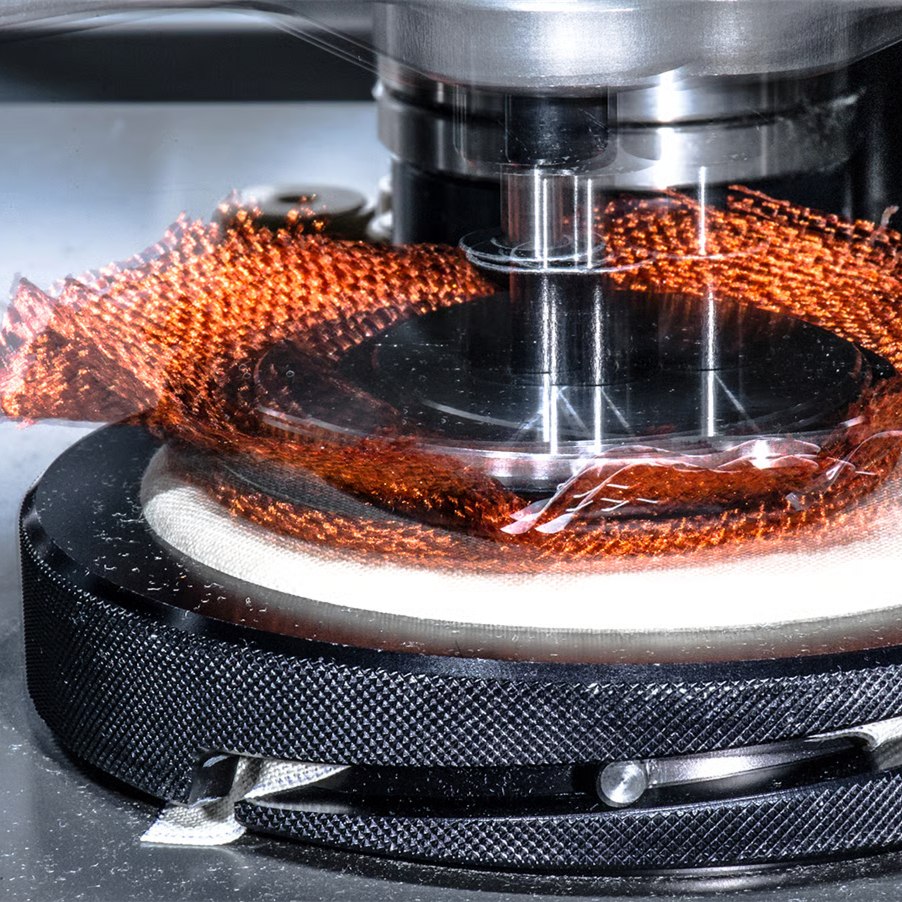

Nylon: Tight Molecular Chains for Strength

Nylon (e.g., nylon 66) is made by polymerizing caprolactam or adipic acid/hexamethylenediamine, then melting and extruding the resin through spinnerets.

The critical step—stretching the fibers—aligns molecules tightly, creating a dense structure that’s super strong and abrasion-resistant (great for heavy use) but slightly more moisture-absorbent.

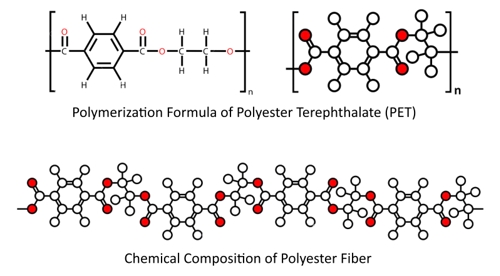

Polyester: Stable Structure with Low Moisture Uptake

Polyester (PET) is produced from terephthalic acid and ethylene glycol, polymerized into PET chips, then melted and spun into fibers. Its rigid molecular structure (with benzene rings) makes it naturally low-moisture, heat-resistant, and cost-efficient, but slightly less tough than nylon.

Nylon’s “warrior” traits (durability for harsh conditions) and polyester’s “everyday” reliability (affordability and easy care) stem directly from their histories and production.

Key Property Comparison

When choosing materials for your custom backpack, the performance of nylon and polyester in key areas such as durability, strength, moisture wicking, elasticity, color retention, weight, flexibility, and reactivity to water and heat directly impacts the ultimate functionality and user experience.

Below is a detailed comparison of the two materials to help you make an informed decision based on your specific needs.

Durability

Nylon demonstrates superior abrasion resistance, outperforming polyester by 30-50% due to its tightly woven fiber structure.

This makes it ideal for heavy-duty applications involving constant friction. Polyester offers adequate durability for everyday use but falls short in extreme conditions.

Strength Performance

In terms of tensile strength, high-denier nylon (e.g., 1000D+) provides exceptional tear resistance, making it perfect for mountaineering backpacks and tool bags.

Polyester maintains more consistent strength with better elastic recovery, suitable for medium-load applications.

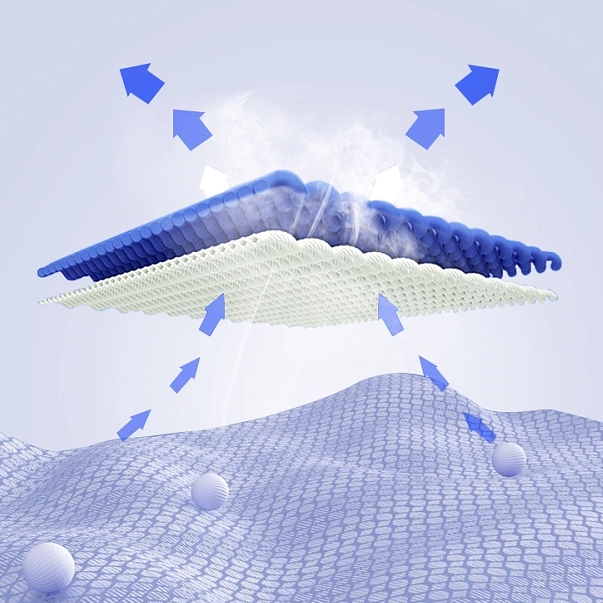

Moisture Management and Comfort

With approximately 4% moisture regain, nylon tends to feel slightly heavier in humid conditions.

Polyester’s minimal 0.4% moisture absorption, combined with mesh constructions, ensures better breathability and comfort during summer use or in tropical climates.

Elasticity and Shape Retention

Nylon’s excellent elasticity allows for quick recovery after compression, making it preferable for ergonomic designs that conform to body contours.

Polyester provides superior dimensional stability, maintaining structured shapes better over time – a crucial factor for business cases and school backpacks.

Colorfastness and Aesthetics

Polyester clearly outperforms in color retention. Its disperse dye compatibility ensures vibrant, long-lasting colors resistant to fading from sunlight or washing.

Nylon colors may gradually fade without proper treatment, particularly in darker shades.

Weight and Structural Properties

At comparable thicknesses, nylon offers a slightly better weight-to-strength ratio with a softer hand feel.

Polyester provides more rigidity, better maintaining structured silhouettes for fashion-oriented designs.

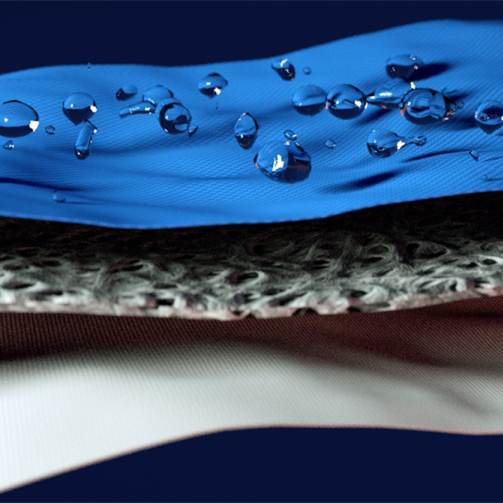

Water Resistance and Thermal Stability

Untreated nylon absorbs about 0.8% water versus polyester’s 0.4%. However, nylon achieves superior waterproofing with PU/TPU coatings.

Polyester demonstrates better heat resistance (melting point 250-260°C vs nylon’s 210-260°C), maintaining stability in high-temperature environments.

Summary Comparison Table

We’ve compiled these critical characteristics into a comparative table based on real-world testing and client feedback, helping you quickly identify which material better aligns with your needs.

| Property | Nylon | Polyester | Notes |

|---|---|---|---|

| Abrasion Resistance | ★★★★★ | ★★★☆☆ | Nylon excels in high-friction use |

| Tear Strength | ★★★★★ | ★★★★☆ | Nylon is preferred for heavy loads |

| Breathability | ★★★☆☆ | ★★★★☆ | Polyester is better for hot climates |

| Shape Recovery | ★★★★☆ | ★★★★★ | Polyester maintains its structure better |

| Color Retention | ★★★☆☆ | ★★★★★ | Polyester colors last longer |

| Lightweight | ★★★★☆ | ★★★☆☆ | Nylon slightly lighter |

| Water Repellency | ★★★☆☆ | ★★★★☆ | Polyester more water-resistant |

| Heat Resistance | ★★★☆☆ | ★★★★★ | Polyester handles heat better |

This analysis demonstrates each material’s unique advantages: nylon dominates in durability and strength for professional gear, while polyester offers better colorfastness, heat resistance, and everyday comfort. Backpack manufacturer has the expertise to strategically select or blend these materials to achieve optimal performance based on specific product needs.

Nylon vs Polyester: Cost Considerations

When customizing a backpack, cost is often a key decision-making factor—and the price difference between nylon and polyester is determined by multiple elements, including raw material costs, production complexity, and market supply-demand dynamics.

We’ve broken down the cost logic of these two materials based on industry data and production expertise, helping you make the optimal choice within your budget.

Direct Cost Comparison: Nylon vs Polyester

Market data from our long-term supplier partnerships (2025 latest quotes) shows that nylon fabric of the same specification (e.g., similar denier/density) generally costs more than polyester:

- Standard nylon fabric (e.g., 500D-1000D): Approximately 13-18 RMB/meter (prices vary based on specific denier, coating processes, and order volume);

- Standard polyester fabric (e.g., 500D-1000D): Approximately 5-8 RMB/meter (lower under the same conditions).

Polyester is typically cheaper than nylon, with fabric costs 35-70% lower for similar specs. This price gap widens in mass production, making polyester ideal for budget-friendly backpacks. Nylon—especially specialty grades (e.g., waterproof or high-strength)—costs significantly more, justifying its use in premium or custom backpacks.

Key Factors Driving the Cost Difference

The cost disparity between nylon and polyester stems from the following core elements

Fluctuations in raw material prices

Nylon is made from caprolactam, a petroleum-based material. Its price is heavily influenced by crude oil market fluctuations, and its refining process is complex, leading to higher costs.

Polyester uses dimethyl terephthalate and ethylene glycol. Its production is more stable, with ample raw material supply and smaller price swings compared to nylon.

Processing difficulty and process cost

Nylon needs more complex processing – like multiple coatings for waterproofing – raising costs. Polyester dyes more easily, requires simpler finishing, and cuts costs.

Additionally, specialty nylon (like Cordura) demands higher-precision equipment due to its patented high-strength properties, further raising production costs.

Market supply and demand relationship

Nylon is highly sought-after in outdoor gear and premium luggage due to its superior performance. High-grade nylon is often in short supply, driving up prices.

Polyester, however, has broader applications (like apparel and home textiles), facing fiercer market competition and more stable pricing.

Customization additional costs

For backpacks needing special textures, prints, or functional treatments (e.g., antibacterial/flame-retardant), the cost gap between nylon and polyester widens.

Nylon’s chemical structure demands pricier additives and longer processing for customization, while polyester’s modification technology is more mature, keeping costs better controlled.

The cost difference between nylon and polyester isn’t just about “which is more expensive”—it’s about paying a reasonable premium for specific performance advantages.

Our recommendation: Clarify your backpack’s primary purpose (e.g., does it need extreme durability? Is ultra-low cost the priority?), then combine the material property analysis from earlier sections to find the optimal balance between functionality and budget.

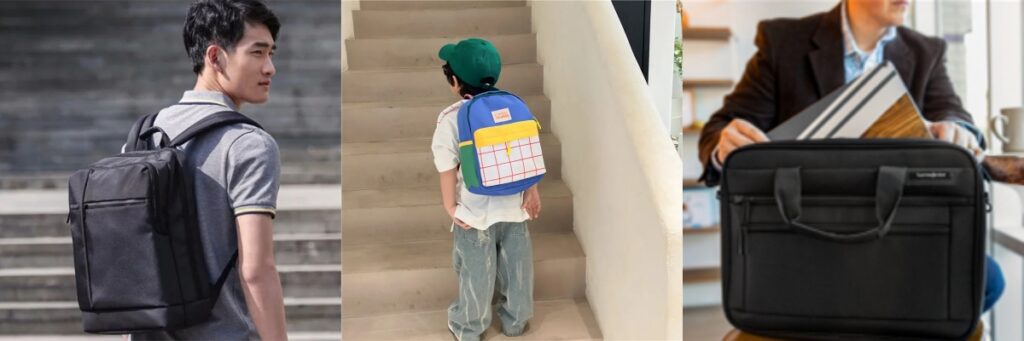

Application Analysis: Choosing the Right Material

With 25 years of manufacturing expertise, we’ve developed precise material selection guidelines for various backpack categories. This professional analysis will help you make optimal fabric choices.

Professional Outdoor Backpacks

Recommended Material: High-density nylon (500D-1000D)

Key Advantages: Exceptional tear resistance and abrasion performance for extreme conditions

- Mountaineering packs

- Tactical/military bags

- Professional camera bags

- Industrial tool carriers

Everyday Commuter Series

Ideal Material: 420D-600D polyester

Key Benefits: Excellent shape retention and colorfastness for daily professional use

- Business briefcases

- Urban commuter backpacks

- Laptop bags

- School backpacks

Specialty Application Packs

- Fire/rescue: Flame-retardant treated nylon

- Medical bags: Antimicrobial-coated polyester

- Cycling packs: High-breathability polyester mesh

- Dive bags: TPU-laminated nylon

Sports & Casual Collection

Performance Synergy: Nylon provides core strength while polyester lining reduces weight

- Main body: 420D nylon (balance of lightness/strength)

- Stress points: 1680D ballistic nylon

- Lining: 210D polyester

Travel Luggage Line

Pro Tip: Prioritize nylon’s impact resistance for frequently checked luggage

- Rainy regions: PU-coated 600D polyester

- Arid climates: 500D nylon

- Checked baggage: 1680D ballistic nylon

Quick Care Guide for Nylon & Polyester Backpacks

Proper maintenance is key to extending your backpack’s lifespan. While both nylon and polyester are durable materials, following these care instructions will ensure they stay in top condition longer.

Nylon Backpack Care

- Regular cleaning: Hand wash in cold water with mild detergent

- Tough stains: Gently brush with soft soft-bristle brush

- Drying: Air dry in shade – avoid direct sunlight

- Heat warning: Keep away from high heat (max 120°C/248°F)

Polyester Backpack Care:

- Machine washable (use a laundry bag for protection)

- Stain removal: White vinegar solution works well on grease

- Drying options: Low-heat tumble dry or line drying

- Wrinkle-resistant: Rarely needs ironing

For a complete step-by-step washing tutorial with photos, check out our comprehensive guide: The Ultimate Guide to How to Wash a Backpack.

Recycling & Environmental Impact

When choosing backpack materials, sustainability matters. Here’s how nylon and polyester compare in recycling and eco-friendliness to help you make a greener choice.

- Polyester: More eco-friendly now—its recycling tech (especially physical methods like shredding and melting) is widely used, turning old polyester into things like stuffing or industrial fabrics. China’s mature PET recycling system helps reuse it efficiently. It’s also easier to recycle at scale, with lower production energy than nylon in most cases.

- Nylon: Trickier to recycle now—its chemical recycling (breaking down molecules) is complex and costly, though tech is improving. It needs high-tech processes to reuse, but future breakthroughs (like enzyme recycling) could change this.

Quick Eco Comparison

| Factor | Nylon | Polyester |

|---|---|---|

| Recycling Ease | Harder (needs advanced tech) | Easier (common methods) |

| Recycled Uses | High-performance needs only | Stuffing, fabrics, etc. |

| Production Impact | Higher energy use | More energy-efficient |

| Future Potential | Improving (new tech coming) | Stable & widely recycled |

- Tip: For immediate sustainability (e.g., corporate green projects), choose recycled polyester (rPET) or standard polyester. If you need top durability and trust future recycling advances, nylon is still a strong performer. We’ll help you balance performance, cost, and eco-responsibility for your custom backpacks.

FAQ

Q: Which material is better for printing logos or designs?

Polyester holds prints better due to superior dye retention. Nylon works well for embroidered logos.

Q: Which is easier to repair if torn?

Nylon is easier to patch or sew due to its flexibility. Polyester may fray more at seams.

Q: Will backpacks made of these two fabrics smell?

Polyester is more odor-resistant—it absorbs less moisture (only 0.4%) and is less likely to harbor bacteria. Nylon absorbs slightly more moisture (about 4%) and may be more susceptible to odor in humid environments if not cleaned promptly, but the difference is not significant.

Q: Which is safer for children’s backpacks?

Both are safe (meeting international environmental standards), but polyester is more recommended—it’s cheaper and stain-resistant, and easy to clean (suitable for cleaning after children get dirty). Nylon offers lightweight options (such as 20D ultra-thin nylon) that combine durability with a soft touch.

Q: Which is more cost-effective for small custom orders (e.g., 100 pieces)?

Polyester is more economical—it has lower raw material and processing costs and offers a more affordable minimum price for small orders. Nylon requires special coatings/processing, but the cost is higher in small orders, making it suitable for medium to large custom orders with a sufficient budget.

Q: What’s the typical difference in the lifespan between nylon and polyester backpacks?

Under normal use, nylon backpacks have a lifespan of approximately 3-5 years, and polyester backpacks have a lifespan of approximately 2-4 years, depending on the intensity of use.